***UPDATED JAN 2024

We pride ourselves on designing the best catalytic converter shields that are unlike any other products out there. This means that there are times we will come back to older designs and implement new features and techniques to improve a product. No other manufacturer cares enough to redo older designs or find ways to make the product better and easier to install.

Transparency is a big deal for us. We believe it builds trust in our company and our products. We get a lot of requests for products and aren't always the quickest to market, but we don't cut corners. Every product is thoroughly tested to make sure we can make the best product for our customers. We want to share our experience with one particular application to demonstrate the rigor we put behind each product and the lessons learned.

For our loyal customers, we have an Upgrade Program, where you can receive upgraded Cat Shield versions at a discount.

View the evolution of our Honda Element Cat Shield below, available for OEM and aftermarket converters.

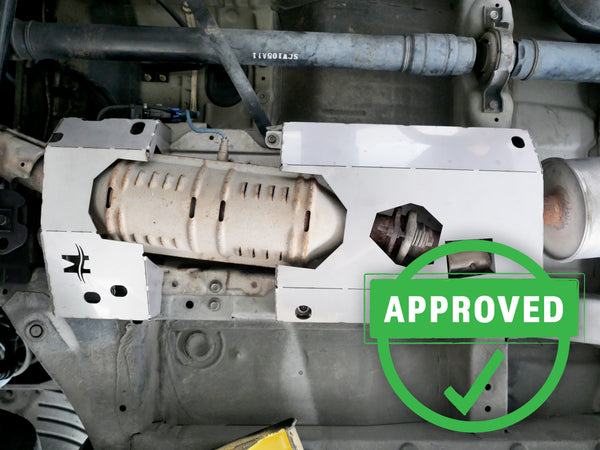

Redesign #3 (Current Version):

Our latest version of the ever-popular Honda Element Cat Shield is incredibly easy to install, requiring significantly less modifications and has multiple louver vents to ensure proper airflow to allow sufficient dissipation of heat while in motion or at idle. This new design also works seamlessly with the OEM running boards.

With this latest design, we had a few goals in mind:

-

Make a shield that requires less drilling. Every other shield out there requires lots of drilling and permanently fastening a shield to your vehicle. With our latest version, you only have to enlarge one existing hole rather than drill new holes.

-

Make a shield that is easier to install. Save time and money with our ingenious design.

-

Offer the best protection for the converter. We only use 304 stainless steel in our design. This is the hardest material to cut through. Aluminum shields won't cut it (pun intended) for the highly sought after Element catalytic converters. Mixed metals are a terrible idea too, as that leads to galvanic corrosion.

-

Prevent as much noise and vibration as possible. We designed the shield to account for as many variants as possible to mitigate vibration.

-

Keep the temperatures down! Just like in our blog, we temperature test our designs to make sure there is no excessive heat retention that could harm your vehicle. Avoid designs that act as tinder boxes and trap in all that radiating heat from your converter.

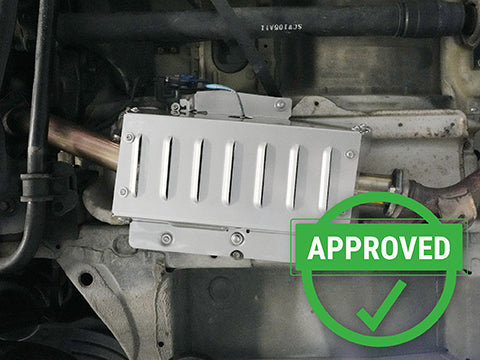

Redesign #2

We learn from failures and from the past. This redesign was our first successful Element shield. Knowing that we had to make some type of structure for the converter, we focused on the most vulnerable sections-the pipe. We had success with a similar problem with our Prius Gen 1 converter, where we left the converter exposed but covered the pipe that thieves target. In this design, we prevent thieves from cutting and ripping off the converter, while also leaving it uncovered so that heat can escape. Our design gives thieves nowhere to cut and does no harm to the vehicle or occupants. In addition to the protection of the converter, occupants, and vehicle, we also provide the convenience of making our shields fully removable and protected by tamper-proof screws. And of course, we think it looks pretty awesome.

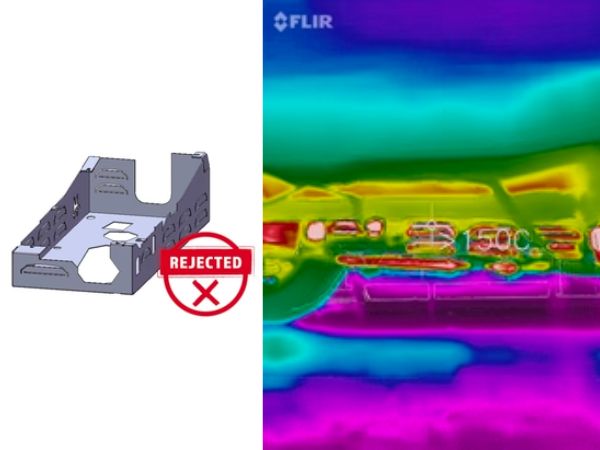

Redesign #1 (temperature test failure)

Wanting to look at ways to release heat from the shield, we designed as many vents and gaps as we could to allow air to flow in and out of the structure. However, despite all the added ventilation and openings to allow heat to escape, the temperature readings were still too high and did not pass our tests (we also tested the inside temperature of the air inside the device, which went beyond the limit of our IR camera of 300 degrees). We saw only marginal temperature differences between this and the original design. At this point, we were fairly certain we had to scrap any design that would box in the converter.

Original Design (temperature test failure)

Our first design was basically a box that protected the converter. It looked like a good concept as it protected the converter and looked similar to the boxy shape of the Element. While our design satisfied our first goal of protecting the converter, it ended up failing our standards of protecting the vehicle and occupants.

After we build a prototype, we run it through a series of driving tests to measure temperature, noise, and vibration. This first concept failed miserably during temperature testing. We use thermal probes during our drive cycles to measure temperature changes inside the areas that our shields cover. We have probes located between the converter and the floor of the vehicle to see how hot it gets. We do this with and without a shield to measure the differences.

We were shocked to see that by encasing the converter, the temperature between the converter and floor board reached up to 700 degrees (nearly 300 degrees hotter with a shield than without) while the vehicle was at a stop. We were literally creating an oven underneath the car. With no way for the heat to escape, it was being trapped inside the structure. What worried us even more was what could happen if someone installed our shield and their converter was failing or overheated. A failed or failing converter can have temperatures reach up to 2,000 degrees. This possibility was unacceptable, and we went to work on a way to address it.

Upping the Game

The challenge is to make a product that offers the best protection while also being as affordable as possible. At Miller CAT, our main goal is to give you the best device possible at the best value. There are certain things on which we will not compromise, and we wanted to give Element owners the best product out there. We felt that we HAD to make our Element shield in 304 stainless steel. We know these owners value quality, ruggedness, and craftsmanship, and we are extremely excited to offer this product to them!

Honda Element Cat Shield™ available now!